top of page

Riteway Brake Dies

The Pinnacle of Precision Tooling

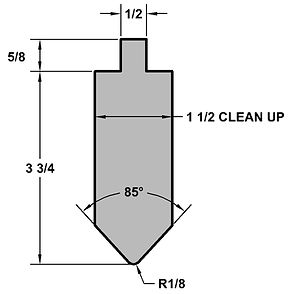

90 & 85 Degree Punches & Dies

General purpose dies are easily modified in many ways to meet special forming and bending requirements - larger or smaller radius, special angles, clearances, etc.

#11

20 Ga

Number 11 punch and numbers 12, 14, 16, and 18 dies are economical dies for low cost forming of light gauge sheet metal, especially for short flange work.

#12

26 Ga

#14

24 Ga

#16

22 Ga

#18

20 Ga

#13

11 Ga

#20

22 Ga

#22

20 Ga

#15

14 Ga

#24

18 Ga

#26

16 Ga

#28 14 Ga

#30

13 Ga

#32

12 Ga

#34

11 Ga

#17

10 Ga

#36

10 Ga

#19

1/4

When forming 10 ga. metals and heavier, we recommend using our numbers 17, 19, 21, and 23 with their respective dies. However, air forming is most common here, in order to keep press brake tonnage requirements to a minimum and to prevent material fracture.

#38

9 Ga

#40

3/16

#42

1/4

#21

3/8

#44

5/16

#46

3/8

#23

1/2

#48

1/2

bottom of page